As the auto industry accelerates toward electrification, battery technology has become one of the most critical levers for progress. For decades, car batteries for internal combustion engine (ICE) vehicles were limited to lead‑acid and related designs, primarily powering ignition systems and electrical accessories. But the rise of electric vehicles (EVs) and hybrids demands far more from electric vehicle battery systems: energy density, longevity, fast charging, safety, cost efficiency, and sustainability.

In this context, questions like what is the expected battery lifespan, how long is EV battery life, how long is hybrid battery life, and what will battery replacement cost are central to both consumer decision‑making and engineering priorities. Meanwhile, the legacy systems—lead‑acid battery and AGM battery (Absorbent Glass Mat)—still play roles in hybrid systems or auxiliary circuits. Let’s explore how battery technology is evolving, what the future holds, and how these shifts will influence car battery life across all vehicle types.

Present Landscape: ICE, Hybrid, and EV Batteries

Before diving into future breakthroughs, it’s helpful to understand the baseline.

- Traditional car batteries (for ICE vehicles) typically use lead‑acid battery chemistry or AGM battery variants. Their main job is to provide power for starting the engine, lighting, electronics, and accessories.

- Typical battery lifespan for these lead‑acid / AGM batteries ranges from 3 to 5 years, though harsh climates or heavy electrical loads can shorten that.

- For hybrid battery life, the high‑voltage battery packs (often nickel-metal hydride or lithium variants) generally last 8 to 10 years, depending on usage and thermal management.

- For EV battery life, modern lithium-ion EV packs are often warranted for 8 to 10 years or around 100,000 to 150,000 miles. Many retain significant capacity beyond that.

These figures shape customer expectations about car battery life in electric or hybrid vehicles. Nonetheless, the next generation of battery innovation could push those lifespan boundaries far forward.

Major Trends Shaping the Future of EV Batteries

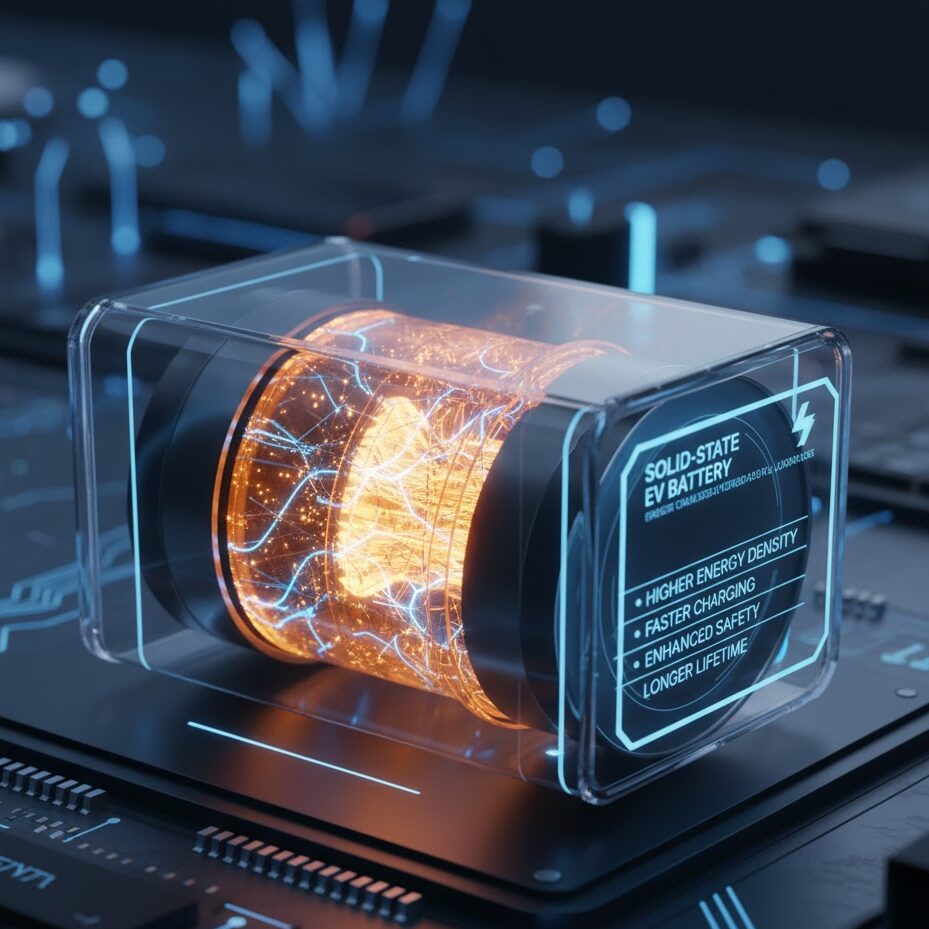

1. Solid-State Batteries

One of the most anticipated leaps is from liquid-electrolyte lithium-ion systems to solid-state batteries. In these systems, the traditional liquid electrolyte is replaced with a solid material, which brings several potential advantages:

- Higher energy density, meaning more charge stored in the same volume, thereby extending the EV battery life and usable driving range.

- Faster charging, since solid electrolytes often allow lower resistance and less side reaction issues.

- Better safety, because solid electrolytes are less flammable and more thermally stable.

- Longer lifetime, with less degradation over many charging cycles.

Automakers and battery firms are targeting commercialization of solid-state cells around 2026–2028.

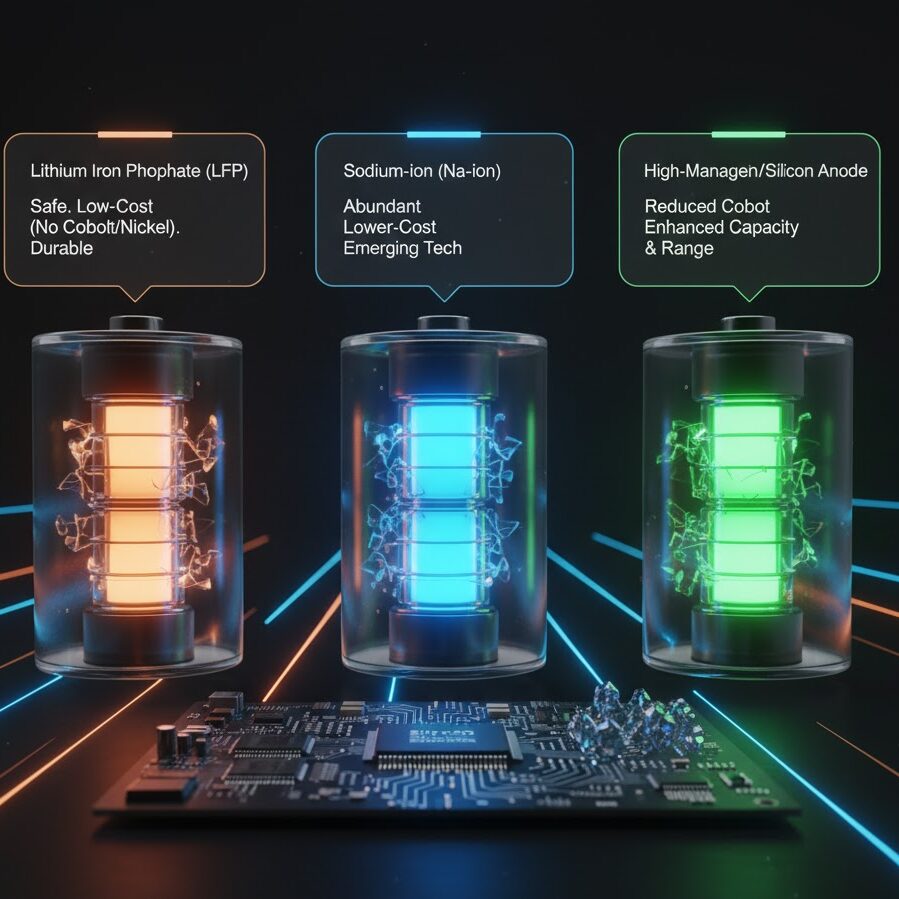

2. New Chemistries and Materials: LFP, Sodium, High‑Manganese

Not all future battery improvements come from replacing lithium-ion entirely — many advances involve evolving current chemistries:

- Lithium Iron Phosphate (LFP) batteries are gaining traction. They are safer, less costly (no cobalt or nickel), and have good cycle durability. Historically used in buses and energy storage, improved cell-to-pack designs are making LFP more viable for mainstream EVs.

- Sodium-ion (Na-ion) battery technology is emerging as a lower-cost, abundant alternative to lithium. While energy density still lags, sodium-ion chemistries are improving and may serve entry-level EVs or augment hybrid systems.

- High-manganese cathodes reduce reliance on cobalt and nickel while boosting stability and lowering cost.

- Silicon-based anodes are being integrated into lithium-ion batteries to replace or augment graphite. Silicon offers much greater lithium-ion storage capacity, which can improve both range and cycle life.

These incremental chemistry advances may significantly uplift electric vehicle battery performance before full solid-state systems become widespread.

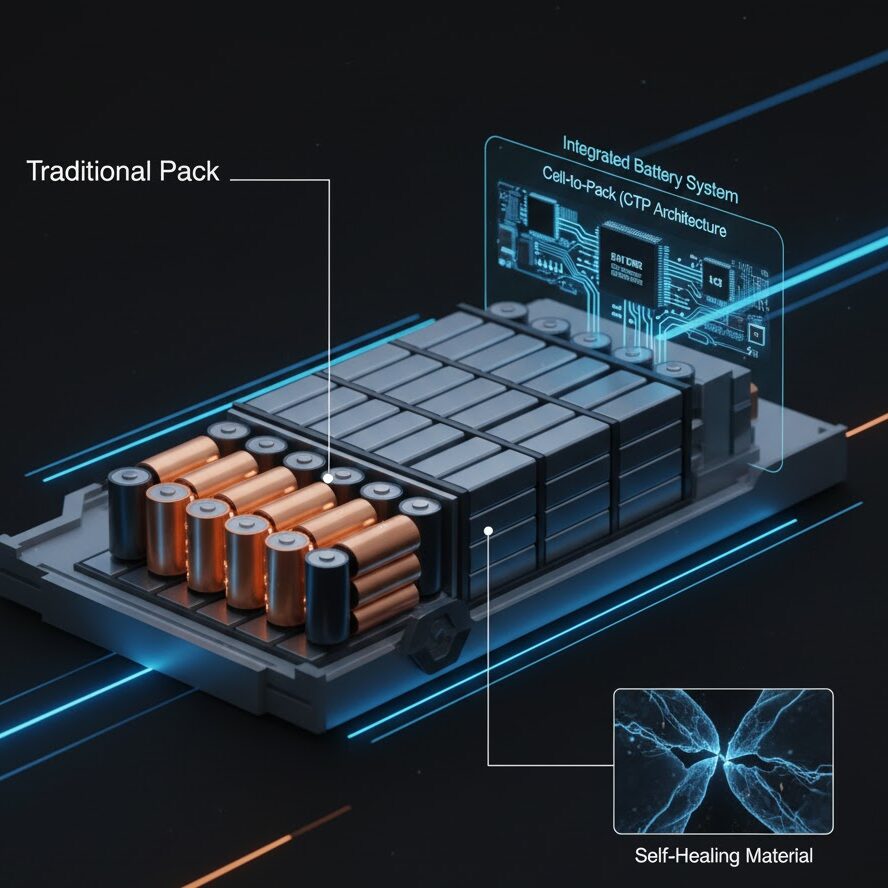

3. Structural & Packaging Innovation: Cell-to-Pack, Integrated Packs

Advancements in how cells are packaged and integrated into battery packs are also important:

- Cell-to-Pack (CTP) architecture, where individual battery cells are integrated directly into the structural pack design (eliminating extra modules), reduces weight and wasted space, boosting energy density.

- Integrated battery systems that combine power electronics, thermal management, and control systems into the pack (a kind of “smart battery”) reduce redundancy, weight, and cost.

- Advanced cooling, thermal management, and self-healing materials help maintain battery health and slow degradation, thereby extending battery lifespan and improving car battery life.

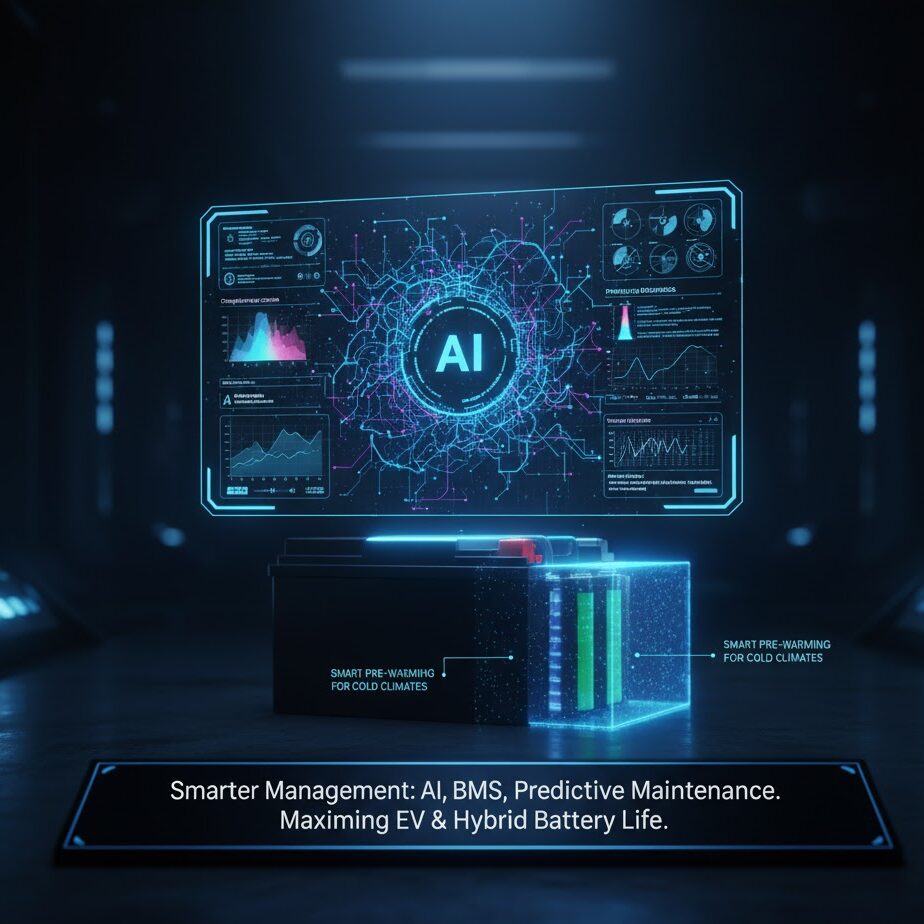

4. Smarter Management: AI, BMS, and Predictive Maintenance

Even with better chemistries and hardware, the brain of the system—the battery management system (BMS)—is essential:

- Machine learning and AI-driven BMS can adaptively manage charge/discharge rates, detect weak cells, and optimize temperature control in real time to maximize longevity. Predictive diagnostics and health monitoring will allow proactive maintenance and early alerts before battery failure. This helps keep EV battery life and hybrid battery life closer to their theoretical maximums.

- For EVs in cold climates, temperature-controlled smart charging algorithms can pre-warm battery cells during charging cycles to reduce stress and degradation.

5. Second-Life & Recycling Ecosystems

As more batteries age out of vehicles, their residual capacity remains significant. Repurposing and recycling lead to sustainability and cost benefits:

- Second-life reuse: Batteries that no longer meet EV CAR performance thresholds can be used in stationary energy storage or grid support, extending useful life.

- Advanced recycling and closed-loop material recovery aim to recapture nickel, cobalt, lithium, and other elements efficiently, reducing raw material costs and environmental impact.

This circular economy approach helps lower the battery replacement cost and ensures more sustainable scaling.

Implications for Battery Lifespan, Maintenance & Costs

Extended Lifespan & Durability

With the advent of solid-state cells, new chemistries, better packaging, and smarter BMS, future EV battery systems may routinely last 15 to 20 years or more, with minimal capacity loss. This dramatically shifts the question from how long do car batteries last to treating the battery as a lifetime component.

The improved durability also benefits hybrid battery life, allowing hybrid packs to last even longer than current norms.

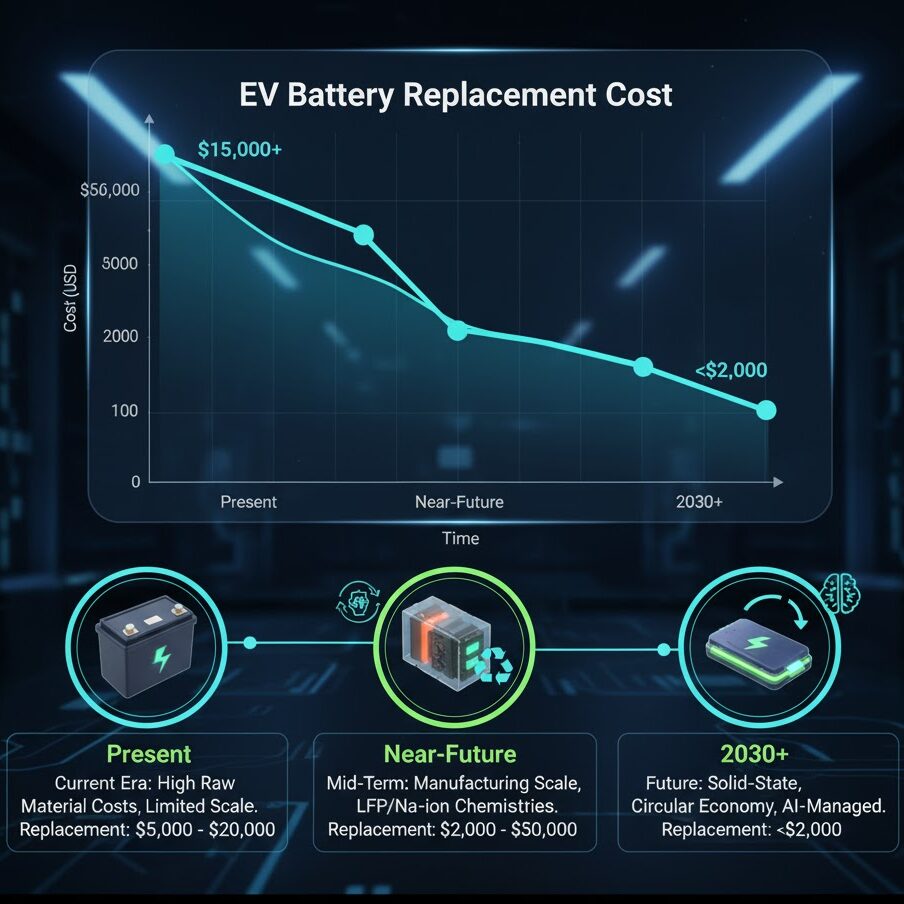

Lower Replacement Costs

As technology matures, manufacturing scales, and recycling loops close, the battery replacement cost for EVs is expected to decline steeply. At present, EV battery packs can cost thousands of dollars, but future economies of scale and lower raw material dependencies should make replacements comparable with other major vehicle components.

Reduced Maintenance & Better Reliability

Unlike lead-acid or AGM battery systems that require periodic checks, watering, terminal cleaning, and voltage balancing, future EV and hybrid battery systems will demand far less maintenance. The AI‑driven BMS can autonomously manage cell balancing, detect faults, and preserve car battery life without manual intervention.

Because many EV battery packs will be sealed units, car battery maintenance in electric vehicles becomes minimal, shifting maintenance focus to cooling systems and software updates.

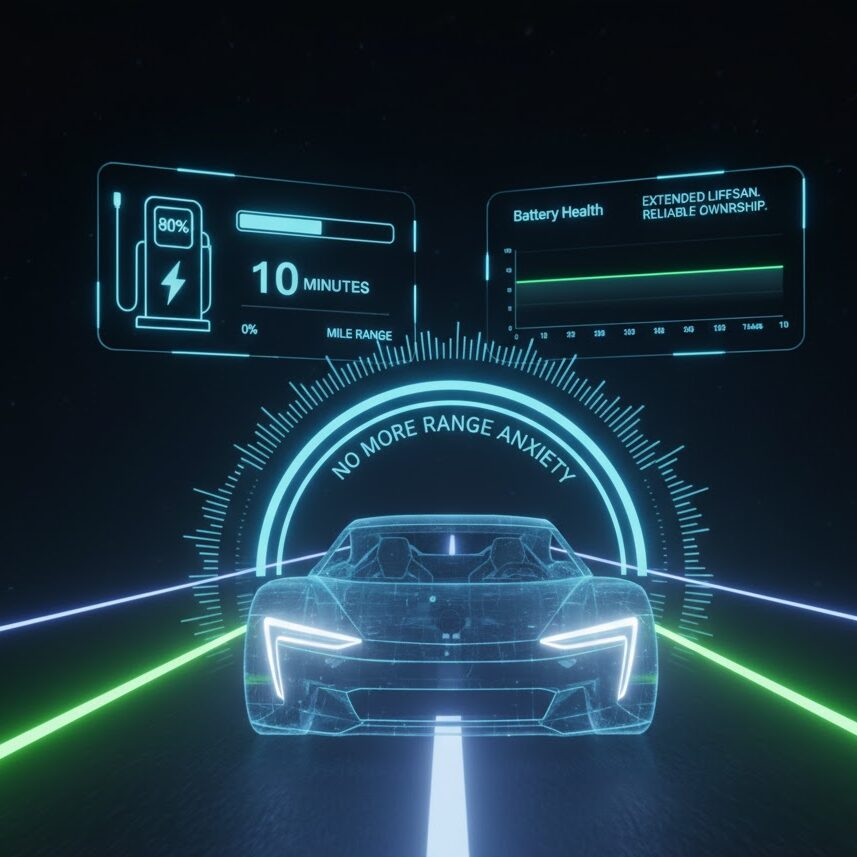

Performance & Consumer Experience

Higher energy densities, faster charging, and extended driving ranges reduce “range anxiety.” Innovations like 800+ mile ranges and 80% charge in 10 minutes are already being explored.

Additionally, more resilient battery systems will maintain their usable capacity over many years, making EV ownership more reliable and appealing to a broader population.

Overcoming Challenges & Risks

Even with exciting advances, several challenges remain:

- Scaling solid-state battery manufacturing cost-effectively for high volume is still a hurdle.

- Balancing performance and longevity: pushing for ultra-fast charging can accelerate degradation unless managed carefully.

- Material supply and geopolitics: even with sodium-ion or LFP chemistries, demand for lithium, cobalt, nickel, rare earths, and other materials remains significant.

- Thermal management and safety: high energy densities and faster charge rates demand robust cooling systems to avoid thermal runaway.

- Standardization and certification: new battery types will need industry-wide standards for safety, warranties, and recycling.

Nonetheless, the trajectory is clear—battery innovation is at the heart of the EV future.

Conclusion

The future of EV battery technology is poised for a transformation that will reshape how we think about automotive power systems. While legacy car batteries using lead-acid battery or AGM battery chemistry still serve traditional vehicles and auxiliary roles, the leap into high-performance, long-lasting electric vehicle battery systems will redefine battery lifespan, car battery life, and overall vehicle economics.

With solid-state batteries, advanced chemistries such as LFP, sodium-ion, silicon-anodes, smarter management systems, and stronger recycling frameworks, we’re heading toward an era where EV battery life may outlast many other vehicle components. Hybrid battery life will likewise benefit from these breakthroughs. As production scales and technologies mature, battery replacement cost will decrease, making electric mobility more accessible.

In the decades ahead, cars may rarely require battery swaps or replacements, and car battery maintenance will become a thing of the past in EVs. In sum, the evolution underway in battery technology promises to propel the automotive industry into a cleaner, more efficient, and more sustainable future.

For deep dives, reviews, and forward-looking analysis on electric vehicles and battery tech, stay tuned with nexgenwheels.

FAQs – The Future of EV Battery Technology

- How long do EV batteries last in 2025 and beyond?

Most modern EV batteries last 8–10 years or 100,000 to 150,000 miles, but with innovations like solid-state batteries and better BMS (Battery Management Systems), future EV batteries could last 15–20 years with minimal capacity loss. - What is a solid-state battery, and why is it important?

A solid-state battery replaces the liquid electrolyte in lithium-ion batteries with a solid material. This change offers higher energy density, better safety, faster charging, and longer lifespan, making it a key future technology for electric vehicles. - Are LFP and sodium-ion batteries better than lithium-ion?

LFP (Lithium Iron Phosphate) batteries are safer, cheaper, and have good cycle life, though with lower energy density.

Sodium-ion batteries are emerging as a cost-effective alternative due to the abundance of sodium, though they currently lag in energy density. Both are promising for entry-level EVs or specific use cases. - What will EV battery replacement cost in the future?

While current EV battery replacement can cost $4,000–$15,000, advances in battery manufacturing, material sourcing, and recycling are expected to significantly reduce costs, potentially bringing them down to a few thousand dollars in the next decade. - Do EV batteries need regular maintenance?

Unlike lead-acid or AGM car batteries, EV batteries require minimal maintenance. With smart BMS and predictive diagnostics, most EVs will self-monitor and optimize performance, reducing the need for manual checks. - What is the difference between EV and hybrid battery life?

Hybrid batteries typically last 8–10 years, depending on usage and climate. EV batteries are designed for deeper charge/discharge cycles and may last 10–20 years with future tech. Both types are benefiting from advancements in battery chemistry and thermal management. - What happens to EV batteries after they wear out?

Old EV batteries can be given a second life in applications like home energy storage or grid support. Additionally, materials like lithium, cobalt, and nickel are recovered through advanced recycling, reducing waste and lowering the cost of new batteries.

1 Comment

Wonderful web site Lots of useful info here Im sending it to a few friends ans additionally sharing in delicious And obviously thanks to your effort